Expert Tips for Getting the Most Out of litho printing

Expert Tips for Getting the Most Out of litho printing

Blog Article

A Comprehensive Guide to Recognizing Litho Printing Strategies

The world of litho printing, a method stemming from the late 18th century, is an interesting blend of background, art, scientific research and development. Stay with us as we journey right into the fascinating world of litho printing.

The Historic Development of Litho Printing

The historical trajectory of litho printing, a crucial advancement in the world of communication, is a fascinating story of human ingenuity. Birthed in the late 18th century by Alois Senefelder, this technique was at first an affordable technique of releasing theatrical jobs. Lithography, stemmed from the Greek words for 'stone' and 'to compose', utilized a smooth stone surface area to move photos onto paper. The process progressed with the advent of the rotary press, which considerably raised performance (litho printing). In the 20th century, the technology of offset lithography revolutionized the market, permitting mass manufacturing of premium prints. Each stage of litho printing's advancement showcases mankind's unrelenting search of performance and high quality in aesthetic interaction.

Decoding the Scientific Research Behind Litho Printing Inks

Relocating ahead in the expedition of litho printing strategies, the emphasis now shifts to the science behind litho printing inks. The make-up of these inks, their drying process, and color mixing methods create the backbone of this intricate art form. Understanding these aspects is essential to mastering the craft and achieving the wanted print outcomes.

Make-up of Litho Inks

In lithographic printing, the basic role of litho inks can not be overemphasized. The make-up of litho inks differs depending on its function, however generally, they contain two major parts - pigments and automobiles. Pigments, the color-providing elements, are carefully ground bits suspended in the vehicle, a fluid that lugs the pigment onto the printing surface area. The vehicle is a complicated blend of resins, oils, and solvents, which affect the ink's drying time, attachment, and gloss. In addition, numerous additives are existing to boost particular homes like circulation, drying out, and resistance to environmental impacts. Each element plays a vital component in the final print's quality, making the exact formula of litho inks a detailed scientific research.

Ink Drying Refine

From the make-up of litho inks, focus turns to the fascinating procedure of ink drying. Two key methods are made use of in litho printing: oxidative drying out and absorption. Absorption, on the various other hand, involves the ink seeping into the paper fibers, which is a faster process however can lead to much less lively shades.

Shade Mixing Methods

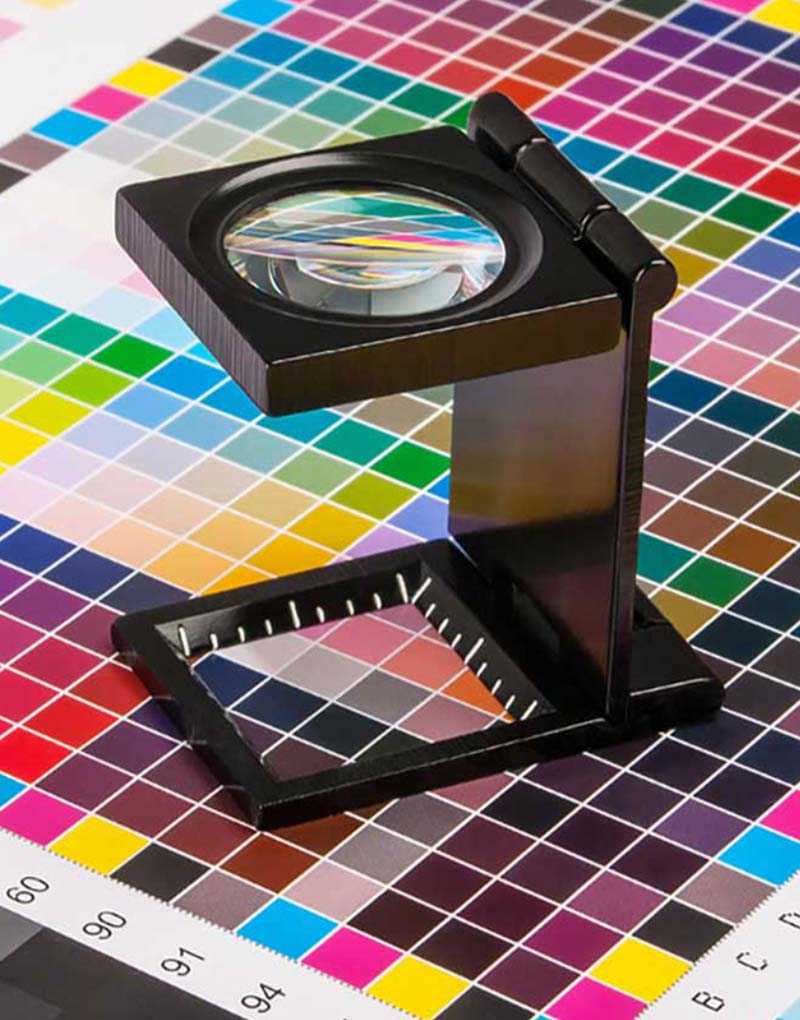

While the drying out process plays a crucial duty in litho printing, the scientific research of shade blending methods holds equivalent relevance. The science behind litho printing inks additionally takes right into account the transparency of the ink, which affects how shades overlay and mix.

The Art and Layout Elements in Litho Printing

Litho printing takes a breath life into art and design via its special elements. Litho printing fits a range of colors, enabling artists to develop dynamic and vibrant prints. This mix of accuracy and adaptability my site makes litho printing a favored choice for many musicians and developers.

Modern Applications of Litho Printing Methods

Litho printing techniques have actually discovered substantial use in the modern business field. Its influence and relevance remain to grow with the development of brand-new technologies and innovations in the area. This section will certainly explore these modern applications and the transformative role they play in the printing sector.

Business Litho Printing Uses

Litho printing remains a vital part of the industrial field. High-volume printing tasks, such as the manufacturing of books, newspapers, and product packaging, depend on litho printing for its capability to deliver superior picture high quality and cost effectiveness. Litho printing additionally gives a wide color spectrum, premium to that of electronic printing.

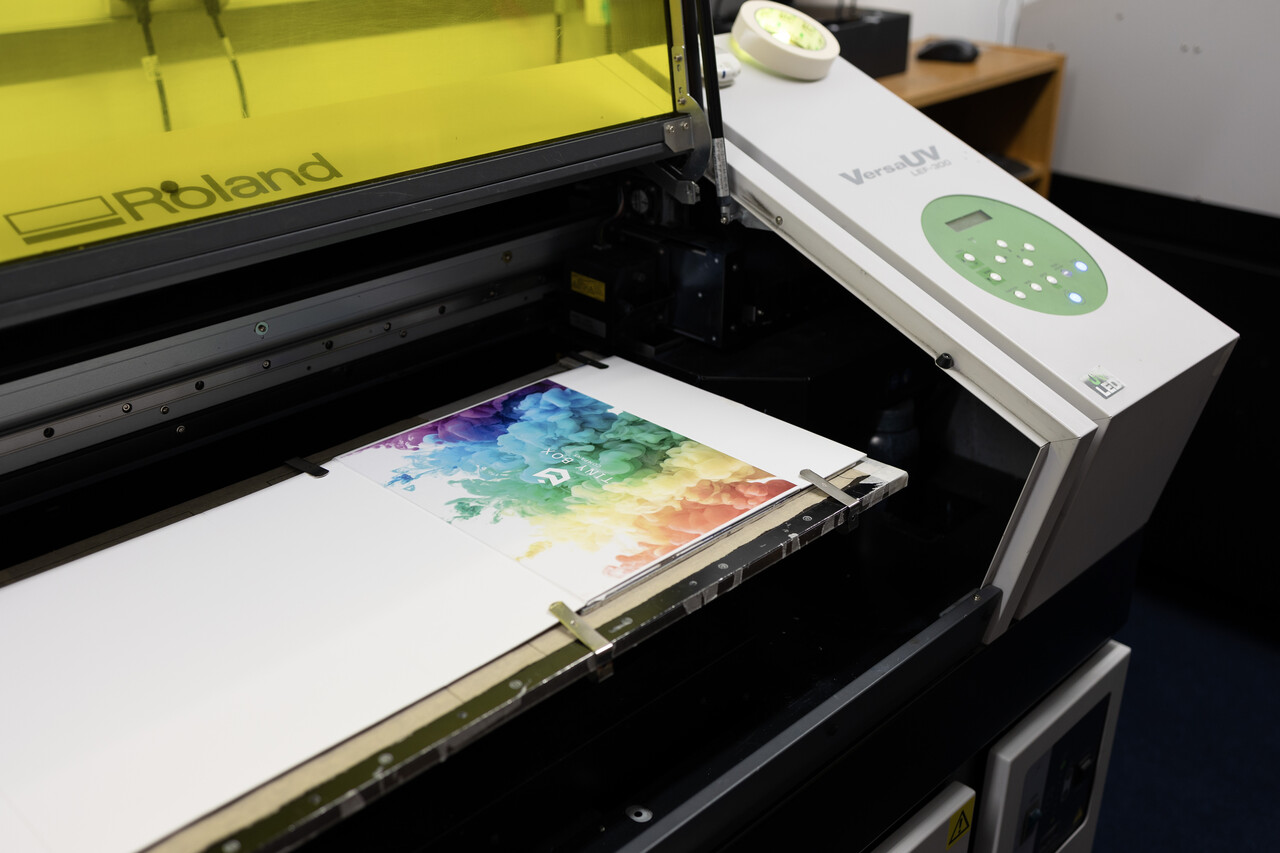

Technologies in Litho Printing

Pressing the borders of typical techniques, modern-day innovations have fueled a host of advancements in litho printing. These advancements have not just boosted the high quality and efficiency of litho prints yet also broadened its application scope. One noticeable development is digital litho printing, which incorporates the merits of digital innovation with litho's top notch result. This hybrid design uses faster setup times, reduced waste, and allows on-demand directory printing. One more significant innovation is the intro of environmentally friendly inks. These inks, made from vegetable or soy-based services, have actually dramatically decreased the industry's ecological impact. litho printing. In addition, the development of sophisticated plate modern technology has streamlined the printing process, resulting in sharper images and improved shade fidelity. These developments emphasize the long-lasting relevance of litho printing in the contemporary globe.

Checking out the Refine of Litho Printing: Detailed

Difficulties and Solutions in Contemporary Litho Printing

In spite of the precision and practice that litho printing happily supports, it is not without its set of contemporary obstacles. Digital litho printing permits for cost-efficient brief runs and simple modification, addressing the issue of variable information. Hence, you can look here while there are obstacles, the litho printing sector is proactively adapting to meet them head-on, guaranteeing its relevance in the future.

Final thought

In conclusion, litho printing, with its abundant history and scientific ins and outs, holds a significant place in the print industry. The future of litho printing hinges on its capacity to adjust to these altering demands, affirming its long-lasting value in an advancing market.

Report this page